-

Leave a Message : info@aabindustrygroup.com

-

Phone : +86 13951823978

Leave a Message : info@aabindustrygroup.com

Phone : +86 13951823978

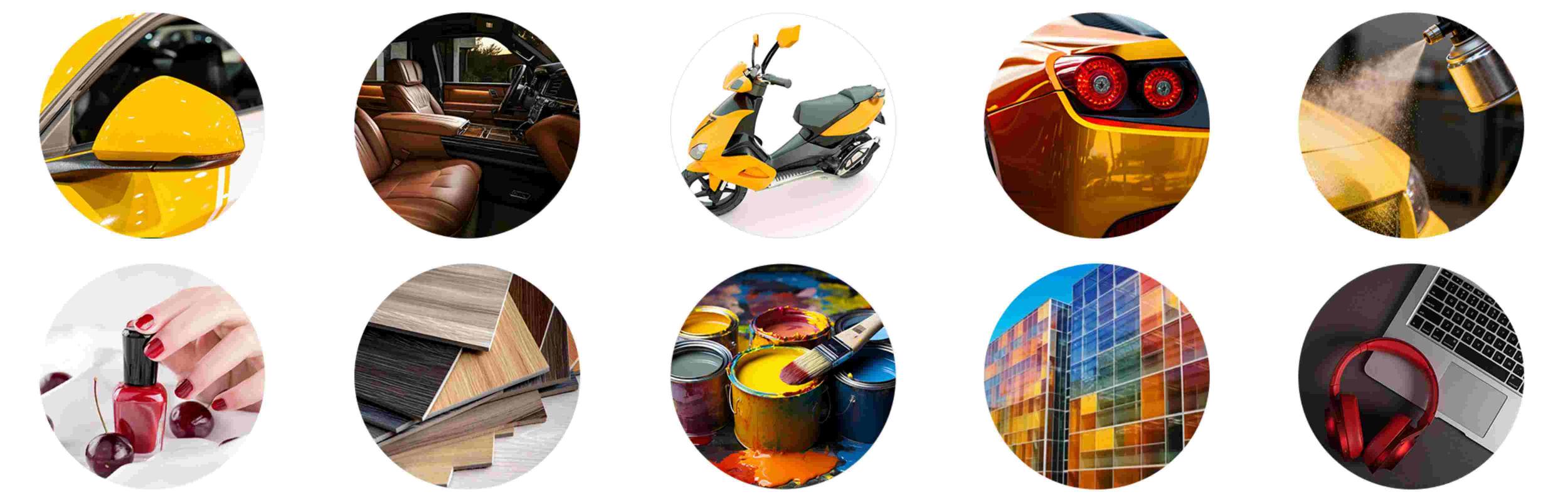

The SIC-S4171 CAB pigment chip revolutionizes pigment preparation by providing a high-performance, blue-shade red alternative to grinding of C.I. Pigment Red 122 solvent pigment paste. With this innovative solution, you can produce ready-to-use pigment paste in just 30-40 minutes—eliminating the need for grinding equipment, dedicated production lines, and major capital investment. This dust-free process also offers superior storage and transportation convenience. Ideal for diverse applications including automotive OEM and refinish coatings, 3C products, wood coatings, UV gel nail polish, plastic coatings, and printing inks, our CAB pigment chips deliver exceptional performance while significantly reducing operational complexity and costs.

Chemical Name :

CAB pigment chipsApplication :

Automotive interior and exterior decorative paints, wood coatings, UV gel nail polish, printing inks etc.Product model :

SIC-S4171Appearance :

Transparent bluish-red hue pigment solidbrand :

KlarintThe SIC-S4171 CAB pigment chip is a high-performance, transparent blue-shade red pigment C.I. pigment red 122 (CAS 16043-40-6, Molecular Formula: C₂₂H₁₆N₂O₂). Composed of 35–45% C.I. Pigment Red 122 and 55–65% cellulose acetate butyrate (CAB-551-0.2), it delivers exceptional performance including grade 8 light resistance, high transparency, and anti-agglomerating properties. Offering superior compatibility and dispersibility, this ready-to-disperse pigment chips enables simple, rapid preparation of color paste or finished paint without grinding, making it ideal for direct incorporation into solvent-based coating systems where consistent color quality and processing efficiency are essential.

Our SIC-S4171 completely eliminates dust generation during handling and processing. This not only ensures a cleaner working environment but also enhances operator safety by minimizing airborne particles. The dust-free characteristic makes these pigment chips particularly suitable for applications requiring strict cleanliness standards. Unlike pigment pastes that typically suffer from flocculation, sedimentation, and quality degradation within 2-3 months, our pigment chips maintain their optimal quality for extended periods. The stable solid form ensures consistent performance throughout the extended shelf life, eliminating concerns about product deterioration during storage. The chips are designed for immediate dissolution when needed, allowing quick preparation of color paste or finished paint without compromising color strength or quality. This on-demand solubility provides flexibility in production planning while maintaining color consistency across different batches.

Klarint SIC-S4171 pigment chips thus provide a comprehensive solution that addresses both operational efficiency and product stability challenges, making them an ideal choice for modern coating applications where reliability and ease of use are paramount.

Comparison of Grinding Pigment Pastes and Dissolved CAB Pigment Chips

|

Item |

Grinding pigment pastes |

Dissolved CAB pigment chips |

|

Production tool |

Grinding production lines |

High speed mixer machine |

|

Labor |

Teams of workers |

1~2 workers |

|

Production time |

8-12 hours/batch |

30~40 minuets |

|

Pigment waste |

5%-10% |

0 |

|

Particle size D50 |

700 nm |

200 nm |

|

High transparency |

No |

Yes |

|

Color stability |

Δe>1.0 (prone to deviation) |

Δe<0.5 (industrial standard) |

|

Shelf life |

6 month |

>2 years |

|

Convenience of storage and transportation |

Dangerous chemical |

Ordinary chemical |

|

Production cost |

High |

Low 20% |

|

Flexibility of production planning |

Fixed |

Flexible for any time and any amount pigment paste |

|

Environmental compliance |

Dust,high energy,pollution discharge |

Compliant |

Our Klarint CAB Pigment Chips' Advantage

1. Extra fine narrow nano Particle size distribution, the pigment paste made of CAB pigment chips has higher color strength, bright hue, excellent gloss, higher transparency.

2. Short Production preparing time, Easily dispersible 30-40 min according flexible production plans any time.

3. Super low investment to produce pigment paste. No need heavy grinding mill investment, just one high speed mixer is sufficient to prepare any amount of pigment paste.

4. Wide latitude of formulation – no additives, ease to formulate color.

5.Environment friendly, high efficient usage, Low dusting, no waste.

6.The quality is stable during storage and transportation with shelf life over 2 years

Typical Properties

|

Product Code |

Product Original Color |

Pigment CI No. |

Pigment Content |

Light Fastness (Level) |

Halogen |

Application |

Features |

|

SIC-S4171 |

|

PR122 |

40 |

8 |

N |

Automotive paint, 3C paint, wood coating, nail polish and so on |

Blue light red |

Specification

|

Pigment structure formula |

C₂₂H₁₆N₂O₂ |

|

Appearance |

Granular pre-dispersed pigment red solid |

|

Solubility |

15 minutes× 8 completely dissolved |

|

Non-volatile% |

98.0 ±2.0% |

|

Covering power |

Equal to or similar to the standard |

|

Color difference |

Dark color ΔE: < 1.0 Pale color ΔE:< 1.0 ΔL:0.00±0.50 Δa:0.00±1.00 Δb:0.00±1.00 |

Our Klarint CAB pigment chips' Application

1. Automotive and electric motorcycles Exterior coating

2. Automotive interior coating

3. Refinish paint

4. Nail polish

5. Wood coating

6. Ink

7. Glass paint

8. 3C paints & coatings, and Others industrial paint

Packaging and Storage

Standard package is 25kg/barrel, accept customized package.

Keep the product un-stacked in dry and closed rooms at normal temperature and air humidity.

To achieve best possible results, we recommend storage under the condition stated above and use within 12 months from delivery.

Tags :

Hi! Click one of our members below to chat on