Which Cellulose Acetate Butyrate is Suitable for Plastic?

Dec 25, 2025

In today's plastics industry, which is pursuing high performance, multi-functionality, and environmental sustainability, specialty additives are playing an indispensable role. Cellulose acetate butyrate (CAB), a specialty resin with a long history but continuously evolving performance, is a "key player" in many high-end applications. Among them, CAB-381-2, with its unique physicochemical properties, has become one of the core materials for improving the surface performance, processing performance, and final quality of plastic products. As a professional supplier that has long provided high-performance solutions to globally renowned companies, China AAB Group is committed to bringing the innovative applications of CAB-381-2 to its global partners in the plastics industry, jointly developing more competitive products.

What is Cellulose Acetate Butyrate?

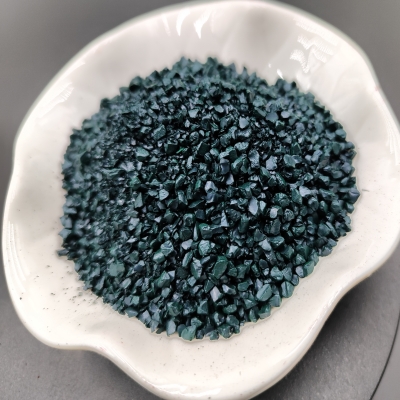

Cellulose acetate butyrate (CAB) is a type of thermoplastic resin obtained by modifying natural cellulose through esterification with acetic acid and butyric acid. The number "381-2" in the model name typically represents key parameters such as the content of acetyl and butyryl groups, and hydroxyl content, which determine its specific solubility, compatibility, rheological properties, and film-forming characteristics. CAB-381-2 usually exhibits excellent transparency, high gloss, good weather resistance and UV resistance, and good solubility in many solvents. As a non-reactive film-forming resin or performance modifier, it can significantly improve the surface properties of base materials.

Applications of CAB-381-2 in the plastics industryThanks to its unique combination of properties, CAB-381-2 finds diverse applications in the plastics industry, primarily as a high-performance additive or modifier:

Key additive for improved surface properties: In the surface treatment of plastic products, especially PVC, ABS, and polyolefins, the addition of CAB-381-2 can significantly improve the surface gloss, smoothness, and feel of the final product, while reducing surface defects.

Main component of scratch-resistant and anti-blocking coatings: CAB forms a hard, wear-resistant, transparent film, often used in the manufacture of scratch-resistant coatings for plastic films and sheets, or to prevent plastic products from sticking together during storage and transportation.

Orientation agent for metallic and effect pigments: In plastic products containing metallic or effect pigments such as aluminum powder and pearlescent pigments (e.g., automotive interior parts, high-end electronic product casings), CAB-381-2 effectively promotes the directional alignment of pigments, achieving a uniform, bright, and visually deep metallic luster effect.

Processing aid and compatibilizer: CAB-381-2 can improve the compatibility of certain plastic blending systems, optimize melt flowability, thereby improving processing efficiency and reducing internal stress in the finished product.

Advantages of Choosing CAB-381-2:

Integrating CAB-381-2 into your plastic formulations or processes offers immediate and crucial advantages for the final product:

Superior Final Appearance: Provides excellent high-gloss and high-transparency surfaces, enhancing product quality and visual appeal.

Enhanced Durability: Improves surface scratch resistance, wear resistance, and chemical resistance, extending product lifespan.

Excellent Processing Adaptability: Compatible with a variety of common resins and solvents, easy to process and disperse, without affecting the performance of the main material.

Reliable Quality Assurance: As a mature specialty chemical, it offers stable performance and consistent batch quality, contributing to stable product quality.

Sustainable Solution: Derived from natural cellulose, it has a certain bio-based background compared to purely synthetic resins, aligning with environmental trends.

Choosing the right specialty chemicals partner is the first step to successful technological innovation. As a group comprised of four companies with extensive experience in production and supply chain management, China AAB Group deeply understands the needs of global customers. Our business spans numerous industries, including plastics, coatings, and adhesives, offering over 100 high-performance products, including functional resins.

We adhere to the business philosophy of "integrity and quality paramount, mutual benefit for all," and are committed to creating value for global customers through continuous innovation and attentive service. The group owns four production bases and has long provided stable supply and flexible solutions to customers in over 20 countries and regions, including Europe, North America, the Middle East, and Southeast Asia.

If you would like to learn more about how CAB-381-2 can address your specific application challenges, or to obtain free samples for testing, please feel free to contact us through our official website. We look forward to starting a successful long-term partnership with you and jointly shaping a future of higher efficiency and superior quality in the plastics industry. Feel free to contact us by info@aabindustrygroup.com or WhatsApp +86 13951823978 for Chinese high performance cost CAB reins products.