-

Leave a Message : info@aabindustrygroup.com

-

Phone : +86 13951823978

Leave a Message : info@aabindustrygroup.com

Phone : +86 13951823978

The SIC-S1080 CAB pigment chip provides a cost-efficient titanium dioxide white solution that effectively replaces conventional extra white (C.I. Pigment White 6) solvent-based pigment pastes. It enables on-demand preparation of precise pigment paste quantities within 30–40 minutes, eliminating the need for grinding equipment or dedicated production lines—significantly reducing both capital investment and operational costs. The dust-free process further lowers handling expenses while simplifying storage and transportation. Combining economic efficiency with versatile performance, this pigment chip is ideally suited for various applications including automotive OEM and refinish paints, 3C coatings, wood coatings, UV gel nail polish, and printing inks.

Chemical Name :

Pre-dispersed pigment chipsApplication :

Automotive paint, nail polish, wood paint, inks, glass paint etc.Product model :

SIC-S1080Appearance :

Granular pre-dispersed pigment solidbrand :

KlarintThe Klarint SIC-S1080 is a pre-dispersed granular pigment preparation based on a high-performance, transparent titanium white (C.I. PW6, CAS 13463-67-7). It is finely dispersed and wetted in a low-viscosity grade of Eastman cellulose acetate butyrate (CAB-551-0.2), ensuring outstanding processability.

Our SIC-S1080 pigment chip delivers excellent light resistance (rated at grade 8) and weather resistance, combined with high transparency and anti-agglutinating properties. Its outstanding compatibility and dispersibility enable simple, rapid preparation of color pastes or finished paints—streamlining your production process. Whether you're developing finishes for luxury automobiles, durable coatings for motorcycles, vibrant colors for plastic products, or elegant wood stains, the Klarint SIC-S1080 provides the consistent performance and reliability required for demanding applications.

The SIC-S1080 is formulated to simplify your process as a user-friendly alternative to traditional titanium white solvent paste grinding. It eliminates the need for dedicated production lines, reducing both initial investment and ongoing operating costs. Furthermore, it overcomes common storage issues associated with solvent pastes—such as flocculation, sedimentation, and coarsening within 2–3 months—by offering an extended shelf life and the ability to be dissolved on demand, thus ensuring consistent quality and reliability.

Comparison of Grinding Pigment Pastes and Dissolved CAB Pigment Chips

|

Item |

Grinding Pigment Pastes |

Dissolved CAB Pigment Chips |

|

Production tool |

Grinding production lines |

High speed mixer machine |

|

Labor |

Teams of workers |

1~2 workers |

|

Production time |

8-12 hours/batch |

30~40 minuts |

|

Pigment Waste |

5%-10% |

0 |

|

Particle size D50 |

700 nm |

200 nm |

|

High transparency |

No |

Yes |

|

Color stability |

Δe>1.0 (prone to deviation) |

Δe<0.5 (industrial standard) |

|

Shelf life |

6 month |

>2 years |

|

Convenience of storage and transportation |

Dangerous chemical |

Ordinary chemical |

|

Production cost |

High |

Low 20% |

|

Flexibility of production planning |

Fixed |

Flexible for any time and any amount pigment paste |

|

Environmental compliance |

Dust, high energy, pollution discharge. |

Compliant |

Our Klarint CAB Pigment Chips' Advantage

1. Extra fine narrow nano Particle size distribution, the pigment paste made of CAB pigment chips has higher color strength, bright hue, excellent gloss, higher transparency.

2. Short Production preparing time, Easily dispersible 30-40 min according flexible production plans any time.

3. Super low investment to produce pigment paste. No need heavy grinding mill investment, just one high speed mixer is sufficient to prepare any amount of pigment paste.

4. Wide latitude of formulation – no additives, ease to formulate color.

5.Environment friendly, high efficient usage, Low dusting, no waste.

6.The quality is stable during storage and transportation with shelf life over 2 years

Typical Properties

|

Product Code |

Product Original Color |

Pigment CI No. |

Pigment Content |

Light Fastness (Level) |

Halogen |

Application |

Features |

|

SIC-MT105N |

|

PW6 |

50 |

8 |

N |

Automotive paint, 3C paint, wood coating, nail polish and so on |

Blue-phase Transparent |

|

SIC-MT106 |

|

PW6 |

50 |

8 |

N |

Automotive paint, 3C paint, wood coating, nail polish and so on |

Blue-phase transparent |

|

SIC-S1080 |

|

PW6 |

80 |

8 |

N |

Automotive paint, 3C paint, wood coating, nail polish and so on |

Extra white |

Specification

|

CAS No. |

13463-67-7 |

|

Pigment content (Pigment%/Resin%) |

80/20 |

|

Appearance |

Granular pre-dispersed pigment solid |

|

Solubility |

15 minutes× 8 completely dissolved |

|

Non-volatile% |

98.0 ±2.0% |

|

Covering power |

Equal to or similar to the standard |

|

Color difference |

Dark color ΔE: < 1.0 Pale color ΔE:< 1.0 ΔL:0.00±0.50 Δa:0.00±1.00 Δb:0.00±1.00 |

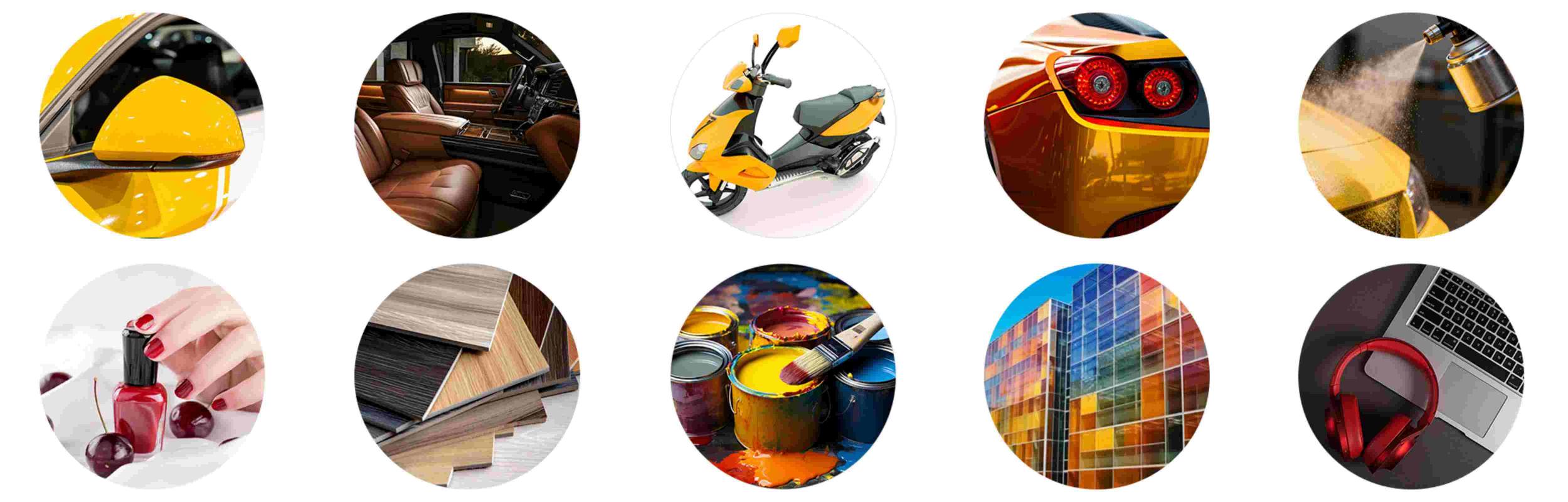

Our Klarint CAB Pigment Chips' Application

1. Automotive and electric motorcycles Exterior coating

2. Automotive interior coating

3. Refinish paint

4. Nail polish

5. Wood coating

6. Ink

7. Glass paint

8. 3C paints & coatings, and Others industrial paint

Packaging and Storage

Standard package is 25kg/barrel, accept customized package.

Keep the product un-stacked in dry and closed rooms at normal temperature and air humidity.

To achieve best possible results, we recommend storage under the condition stated above and use within 12 months from delivery.

Tags :

Hi! Click one of our members below to chat on