-

Leave a Message : info@aabindustrygroup.com

-

Phone : +86 13951823978

Leave a Message : info@aabindustrygroup.com

Phone : +86 13951823978

Kabasph® Chloroether Resin MP60 is a polyvinyl chloride copolymer,used as an adhesive for steel structures, mineral substrates, plastics, shipbuilding and underwater applications, mechanical and automotive engineering, transportation, building protection, printing ink industry, and road marking coatings.This resin basically solves the shortcomings of other chlorine-containing polymer resins.

Chemical Name :

Chlroether Resin MP 60Application :

Chlroether Resin MP 60 is used for special inks or metal adhesivesProduct model :

MP 60Appearance :

White powderbrand :

KabasphKabasph® Chloroether Resin MP60 is a polyvinyl chloride copolymer,used as an adhesive for steel structures, mineral substrates, plastics, shipbuilding and underwater applications, mechanical and automotive engineering, transportation, building protection, printing ink industry, and road marking coatings.This resin basically solves the shortcomings of other chlorine-containing polymer resins. Due to the introduction of vinyl isobutyl ether components, it has excellent bonding properties and is a good chlorinated adhesive. It can be used for anti-corrosion coatings; printing inks, steel structure coatings, wall coatings, road marking coatings, building fire retardant coatings, light metal coatings, deck coatings, ship and container coatings, mechanical and automotive engineering coatings, concrete and asbestos cement, etc.

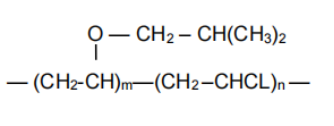

Product Structure

Specification

|

Item |

Unit |

Index |

|

MP-60 |

||

|

Appearance |

/ |

White powder |

|

Chlorine content |

ω/% |

44±1.0 |

|

Volatile compounds |

ω/% |

≤0.50 |

|

Apparent density |

g/mL |

≥0.30 |

|

Rotation Viscosity |

mPa•S |

65±5 |

Features

l Non-toxic, environmentally friendly;

l Strong flexibility;

l Strong heat resistance;

l Strong UV stability;

l Excellent alkali resistance and anti-powdering performance;

l Miscible with alkyd resin, hard resin, acrylic resin, epoxy resin and plasticizer;

l The comprehensive anti-corrosion performance index of the coating is higher than that of chlorosulfonated polyethylene and chlorinated rubber coating.

Application

Chlroether Resin MP 60 is used for special inks or metal adhesives,also widely used in the following fields:

l Heavy-duty anti-corrosion industrial atmospheric anti-corrosion coatings: such as factories, equipment, pipelines, storage tanks, municipal engineering, ports and docks, etc. Chlorinated ether resin coatings have excellent saponification resistance, water resistance, chemical corrosion resistance, and excellent adhesion, and are ideal for anti-corrosion primers and topcoats in industrial atmospheric environments.

l Heavy-duty anti-corrosion coatings for ships: such as various parts of the hull, especially suitable for parts that need to resist seawater corrosion. Chlorinated ether resin coatings have excellent water resistance, salt water resistance, outdoor weather resistance, yellowing resistance and powdering resistance, as well as long-lasting and efficient anti-corrosion properties. The formulated coating dries quickly and is easy to use, which is of great significance in the field of shipbuilding industry anti-corrosion.

l Container coatings and transportation machinery coatings: such as railway, shipping, land transport containers, transportation machinery and dangerous goods tankers. Chlorinated ether resin coatings have excellent adhesion and water resistance, and can maintain stability over a wide temperature range.

l Light metal primer and topcoat: Due to the difficulty of coating non-ferrous metals such as aluminum, zinc, and galvanized steel, ordinary synthetic resin coatings cannot adhere well, causing the coating to peel off from the substrate. Chlorinated ether resin coatings have good adhesion on these metals.

l Special coatings for bridges, marine engineering, and energy engineering: It can also be used for inorganic primers, road marking coatings, plastic coatings, fire retardant coatings, etc.

Package

l 20kg composite kraft paper packaging bag (including inner bag)

l Others: Customized packaging can be made according to customer needs

Storage:

Chloroether Resin MP60 is affected by its own glass transition temperature and is prone to agglomeration in harsh storage or transportation environments such as heavy pressure, high temperature, exposure to sunlight, and humidity. it should be sealed during transportation, avoid extrusion, and avoid heat sources and humid environments.

Chloroether Resin MP60 should be stored in a cool, dry, and ventilated warehouse, and pay attention to moisture, sunlight, and high temperature.

Tags :

Hi! Click one of our members below to chat on