-

Leave a Message : info@aabindustrygroup.com

-

Phone : +86 13951823978

Leave a Message : info@aabindustrygroup.com

Phone : +86 13951823978

As a substitute for chlorinated rubber using carbon tetrachloride solvent method, chlorinated ether resin used in anti-corrosion coatings is not only non-toxic and environmentally friendly, but also has advantages in coating flexibility, heat resistance, UV stability, alkali resistance, and powdering resistance. It can be comparable to additives such as alkyd resin, hard resin, acrylic resin, epoxy resin, etc. Plasticizers are miscible, and its comprehensive anti-corrosion performance indicators are higher than those of chlorosulfonated polyethylene and chlorinated rubber coatings.

Chemical Name :

Chloroether ResinApplication :

Anti-corrosion coatings and composite inks etc.Product model :

MP25Appearance :

White powderbrand :

KabasphThe full name of Chloroether Resin is vinyl chloride-isobutyl vinyl ether copolymer resin, which is polymerized by vinyl chloride monomer, isobutyl vinyl ether monomer and other raw and auxiliary materials. Kabasph® Chloroether Resin MP25 is made by suspension hairpin, which is non-toxic and environmentally friendly,serve as an adhesive in coatings for steel structures, mineral substrates, plastics, shipbuilding, and underwater applications.It has advantages in coating flexibility, heat resistance, UV stability, alkali resistance, and anti-powdering. It is mainly used in anti-corrosion coatings and composite inks,They are compatible with most alkyd resins, acrylic oils, polyacrylic acid resins, liquid epoxy resins, tar and bitumen.

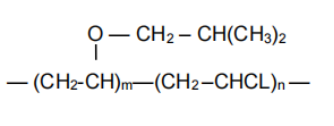

Product Structure

Specification

|

Item |

Unit |

Index |

|

MP-25 |

||

|

Appearance |

/ |

White powder |

|

Chlorine content |

ω/% |

44±1.0 |

|

Volatile compounds |

ω/% |

≤0.50 |

|

Apparent density |

g/mL |

≥0.30 |

|

Rotation Viscosity |

mPa•S |

25±5 |

Features:

Our Chloroether Resin MP25 is mainly made by suspension method. Compared with the traditional solution method, it has better performance and has the following advantages:

l Non-toxic and environmentally friendly;

l Strong flexibility,heat resistance and UV stability;

l Excellent alkali resistance and anti-powdering performance;

l Can be miscible with alkyd resin, hard resin, acrylic resin, epoxy resin and plasticizer;

l The comprehensive anti-corrosion performance index of the coating is higher than that of chlorosulfonated polyethylene and chlorinated rubber coating.

Compatibility

|

Vinyl Chloride Copolymers |

Polyacrylates |

Unsaturated Polyester Resins |

Maleic Acid Resins |

|

Cyclohexanone Resins |

Aldehyde Resins |

Coumarone And Hydrocarbon Resins |

Alkyd Resin |

|

Natural Resin |

Drying Oil |

Plasticizer |

Tar |

|

Asphalt |

|

|

|

Application

MP25 is widely used in heavy-duty anti-corrosion coatings. Its structure is easy to bond. It is suitable for coatings exposed to dry air and physical drying conditions, such as steel structures, container coatings, ship coatings, and industrial anti-corrosion coatings,also can be used in other fields:

l Industrial anti-corrosion coatings, such as factory buildings, equipment, pipelines, storage tanks, municipal engineering ports and docks, etc.

l Ship coatings, suitable for all parts of the hull, can well resist sunlight exposure and seawater erosion.

l Transportation coatings, in addition to containers, there are also transportation machinery, dangerous goods tankers, etc.

l Light metal primer and topcoat, such as garage doors and windows, roof rain gutters, balconies, lamp posts and highway anti-collision isolation panels, etc.

l Large key projects, such as bridges, marine engineering and energy engineering.

Package

l 20kg composite kraft paper packaging bag (including inner bag)

l Others: Customized packaging can be made according to customer needs

Storage:

Chloroether Resin MP25 is affected by its own glass transition temperature and is prone to agglomeration in harsh storage or transportation environments such as heavy pressure, high temperature, exposure to sunlight, and humidity. it should be sealed during transportation, avoid extrusion, and avoid heat sources and humid environments.

Chloroether Resin MP25 should be stored in a cool, dry, and ventilated warehouse, and pay attention to moisture, sunlight, and high temperature.

Tags :

Hi! Click one of our members below to chat on